Improve productivity

LEADING MANUFACTURING SOLUTIONSIMPROVE PRODUCTIVITY > ELECTRONICS MANUFACTURING SOLUTIONS

Mycronic Group, now including ViTechnology, delivers solutions that are highly flexible, precise and cost efficient.

With more than 30 years experience, the Mycronic Group continue to pioneer technologies that shape our world and power increasingly complex automated productions.

Products

- + PICK AND PLACE MACHINES

- + JET PRINTERS

- + TABLE TOP DISPENSING

- + INLINE DISPENSING

- + CONFORMAL COATING

- + STORAGE SOLUTIONS

- + SOLDERPASTE INSPECTION SYSTEM

- + AUTOMATED OPTICAL INSPECTION SYSTEM

You may also be interested in

Can’t find what you’re looking for?

The solutions you’ll find featured here are geared specifically for the needs of Australian and New Zealand industry. Yet by no means do they constitute a complete list. We often work with our partners to source solutions for clients tailored specifically to their needs.

Contact us directly to find out more about how we can assist.

MYCRONIC

+ Pick and place machines

The future of intelligent productivity

Get more jobs done in less space. Switch effortlessly from full volume to batch size one. Handle a wider range of components with uncompromising production quality, total stock accuracy and complete traceability down to an individual PCB serial number.

The MY300 delivers new levels of precision and flexibility in

a faster, smaller and smarter format. A powerful inventory management system is the backbone of this lean manufacturing solution. It combines innovative feeder technology and automatic storage with full material tracking and paperless operator guidance.

Key benefits

- Agilis feeder technology

- Precise material handling

- Strong software suite

Like to know more?

MYCRONIC

+ Jet printers

Next generation in jetting

The need for denser boards, a wider range of miniaturized components and more NPIs, combined with erratic production schedules, means the future of surface mount technology production is becoming increasingly complex. As these challenges go mainstream, productivity suffers. Mycronic, have devoted decades of experience to solving precisely these challenges and have developed some of the industry’s fastest, most flexible and precise jet printing and dispensing systems.

Key benefits

- Faster changeovers

- Compact footprint

- Dual heads for productivity

- Dual lanes for smart board handling and buffering

- High-speed high-accuracy dispensing

- Solder paste and a wide range assembly fluids

- Board revisions on-the-fly and changeovers in no time

Like to know more?

MYCRONIC

+ Table top dispensing

From protoyping to mass production

From advanced prototyping to batch production, these systems are designed with flexibility and configurability in mind. Whether gasketing electrical housings or applying underfill on a BGA, scalability into volume batches and repeatable system output allow you to develop and mature your process on a single system.

Key benefits

- Easy to use

- Higher accuracy

- Low cost of ownership and maintenance

- Easy customisation

- Proven performance in wide-ranging applications

Like to know more?

MYCRONIC

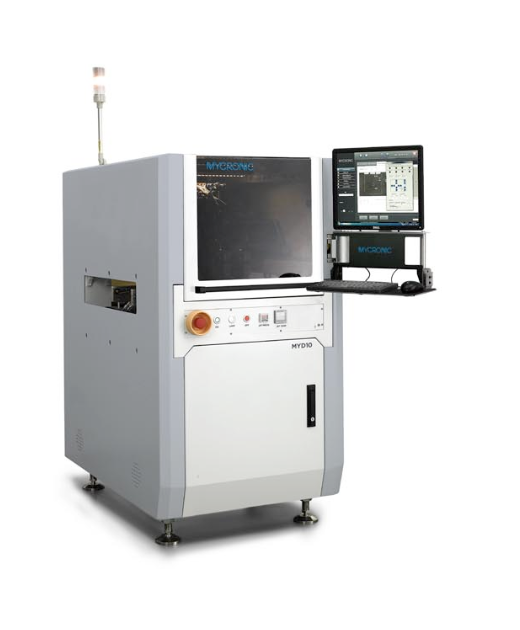

+ In-line dispensing

Fully automated compact dispensing

The MYD Series of dispensers are tailored to exceed your requirements whether it be long boards, cleanroom environment, high precision or general purpose dispensing. This family of dispensers has been proven in 24/7 environments to be ready for your current and future applications.

From semiconductor packaging to electronics enclosures, Mycronic’s in-line dispensing solutions honours the fact that no two client’s requriements are the same.

Key benefits

- 24/7 production

- Low maintenence

- Unmatched production value

- Semi or full automation

- High-precision dispensing volume control

Like to know more?

MYCRONIC

+ Conformal coating

Protecting electronics with precision and versatility

Coating has evolved from a niche process into a mainstream requirement due to electronics being placed into consistently harsher environments where protection is key.

The MYC50 is a high-performance conformal coating system that ensures non-stop throughput across a range of high-volume applications. Thanks to a robust frame structure and advanced motion configuration systems, it gives manufacturers the ideal combination of speed and precision for an endless variety of coating demands.

Key benefits

- Valves for any application

- High-precision

- Strong automation software

- Fast and stable operation

- Automated spray pattern changeovers

- Flexible multi-axis control for complex processes

- Powerful process controls for enhanced quality

- Barcode-defined program selection

Like to know more?

MYCRONIC

+ Storage solutions

Intelligent material handling

The SMD Tower is an automated, highly flexible and expandable buffer storage unit designed for deployment near the production line.

Regardless of whether you request a single reel, tray or automatically process a complete kitting list, the system records every movement and tracks all stored reels and component quantities.

A unique identification code ensures that the correct article is always provided or stored, making mix-ups impossible. Return-to storage is just as quick and convenient. A SMD Tower needs just one square meter of floor space to store up to 1120 reels and can be integrated with existing material handling systems.

Key benefits

The cost-saving potential associated with storage solutions is significant:

- 75% reduction of labor cost

- 50% reduction in P&P downtime

- 90% reduction of retrieval time

Like to know more?

VI TECHNOLOGY BY MYCRONIC

+ Solder paste inspection system

Overcome limitations and satisfy inspection needs

The PI Series allows you to easily implement Solder Paste Inspection (SPI) in to any PCBA line. The intutitive nature of these new generation systems make them easy for staff to operate and removes the need for extensive specialised machine training.

With its small footprint, all models are fitting in the modern assembly line.

Key benefits

The cost-saving potential associated with storage solutions is significant:

- Uprecedented simplicity – operators, not just engineers, can program the machine.

- Inspect without effort – PI is the only SPI to program automatically.

- Accuracy and repeatability – PI’s patented Z-referencing technology overcomes the limitation of traditional SPIs and brings unprecedented accuracy to paste volume measurement

- Control print process to increase yield

Like to know more?

VI TECHNOLOGY BY MYCRONIC

+ Automated optical inspection

Overcome limitations and satisfy inspection needs

K Series and K Series3D are the reference in Automated Optical Inspection (AOI), allowing 2D and 3D inspection with very low false calls rate, for both pre-reflow and post-reflow.

The K Series and K Series3D offer a scalable solution for a broad range of applications, requiring high reliability and thorough defect coverage.

Key benefits

The cost-saving potential associated with storage solutions is significant:

- Superior technology

- Complete defect coverage – increase your test coverage by adding 3D to conventional 2D inspection

- Reduce false calls rate

Like to know more?