TOP-Energy

ENERGY SOFTWARE SOLUTIONSee how TOP-Energy is being used to identify issues, solve problems and save money.

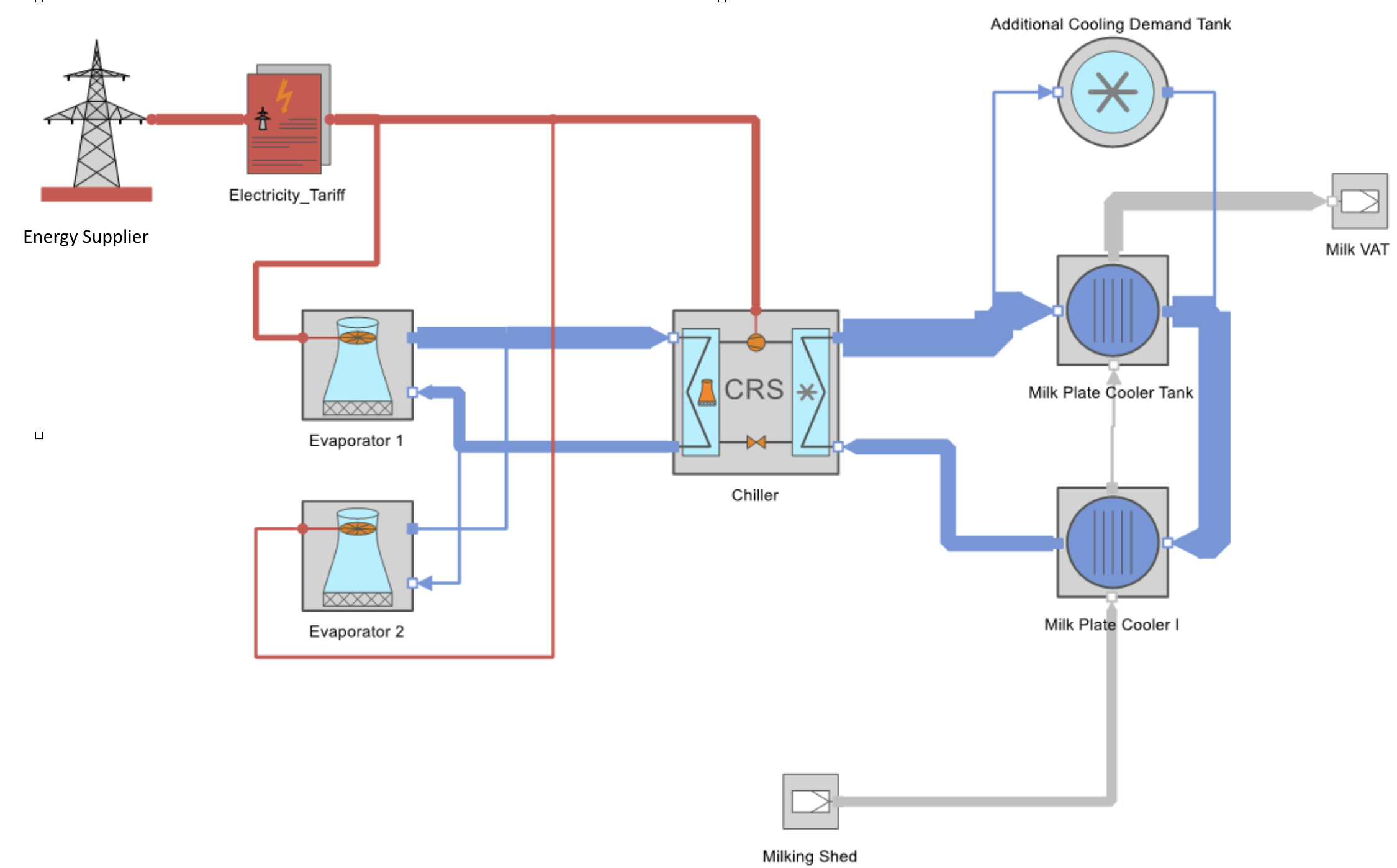

More efficient milk production

Task

Identify potential cost savings in the manufacturing process of dairy products.

Solution

Model and analysis the production process from different views including mass flow, energy, costs and ecology.

Outcome

The analysis showed a huge amount of electric energy was required for micro-filtration and large amounts of energy were being lost across the board. It also identified room for heat recovery in the pasteurization process.

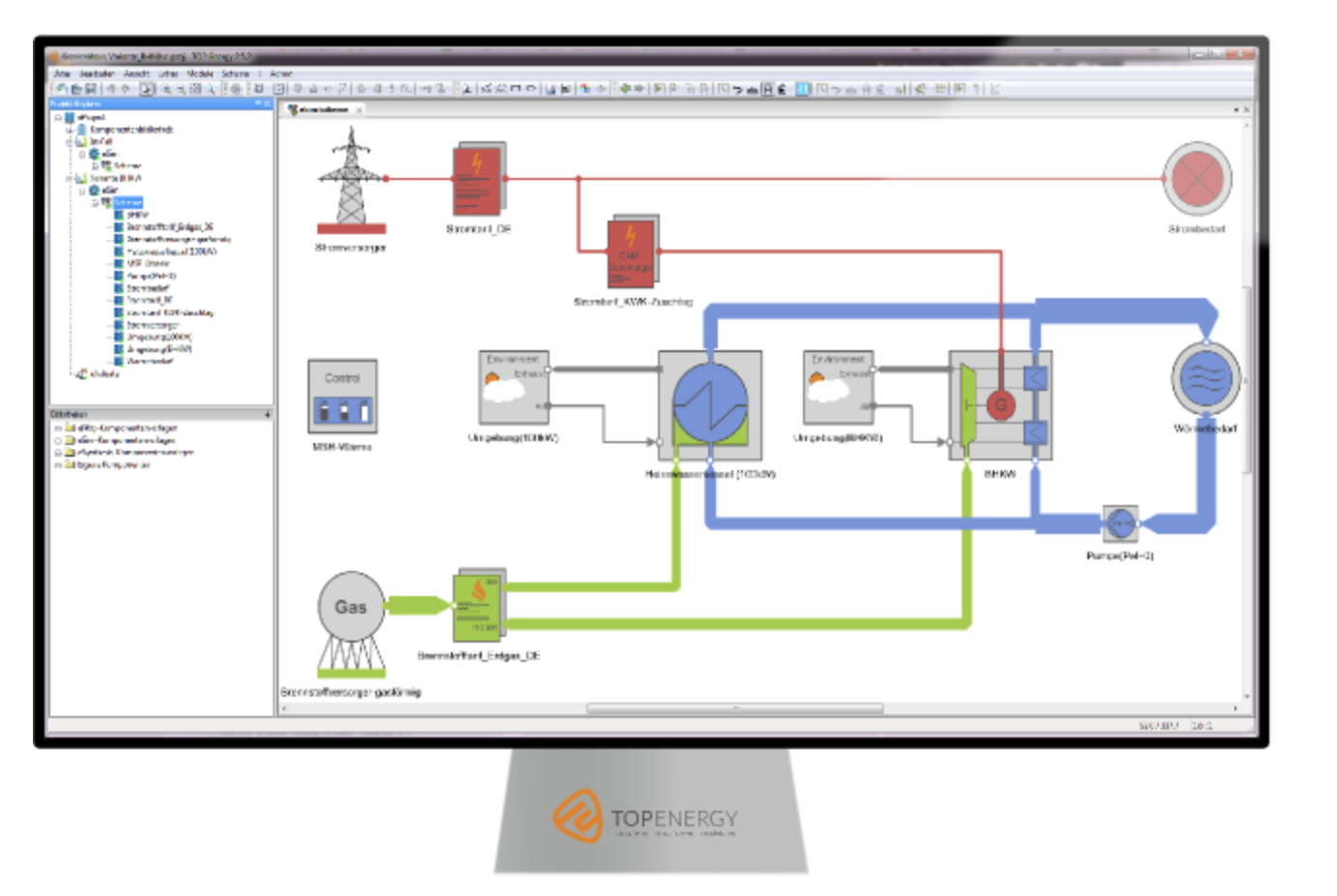

Analysis of the energy supply system at a hospital

Task

The energy system of a hospital with 900 beds consists of two hot water boilers with a thermal capacity of 1,000 kW and 750 kW and a CHP. The CHP is defective and the heat supply is entirely dependent on the two boilers. Electrical energy is obtained from the local electricity supplier. The hospital would now like to examine whether the repair of the CHP is economically viable or whether it should consider other system variants.

Solution

Modelling the actual case scenario and creating different system variants (repair of CHP, new CHP and use of storage).

Outcome

• The purchase of a new CHP plant turned out to be the most economical variant

• The payback period was two years (only a few months longer than the repair of the old CHP)

• A key factor was CHP support

• The use of storage was not found to be economical

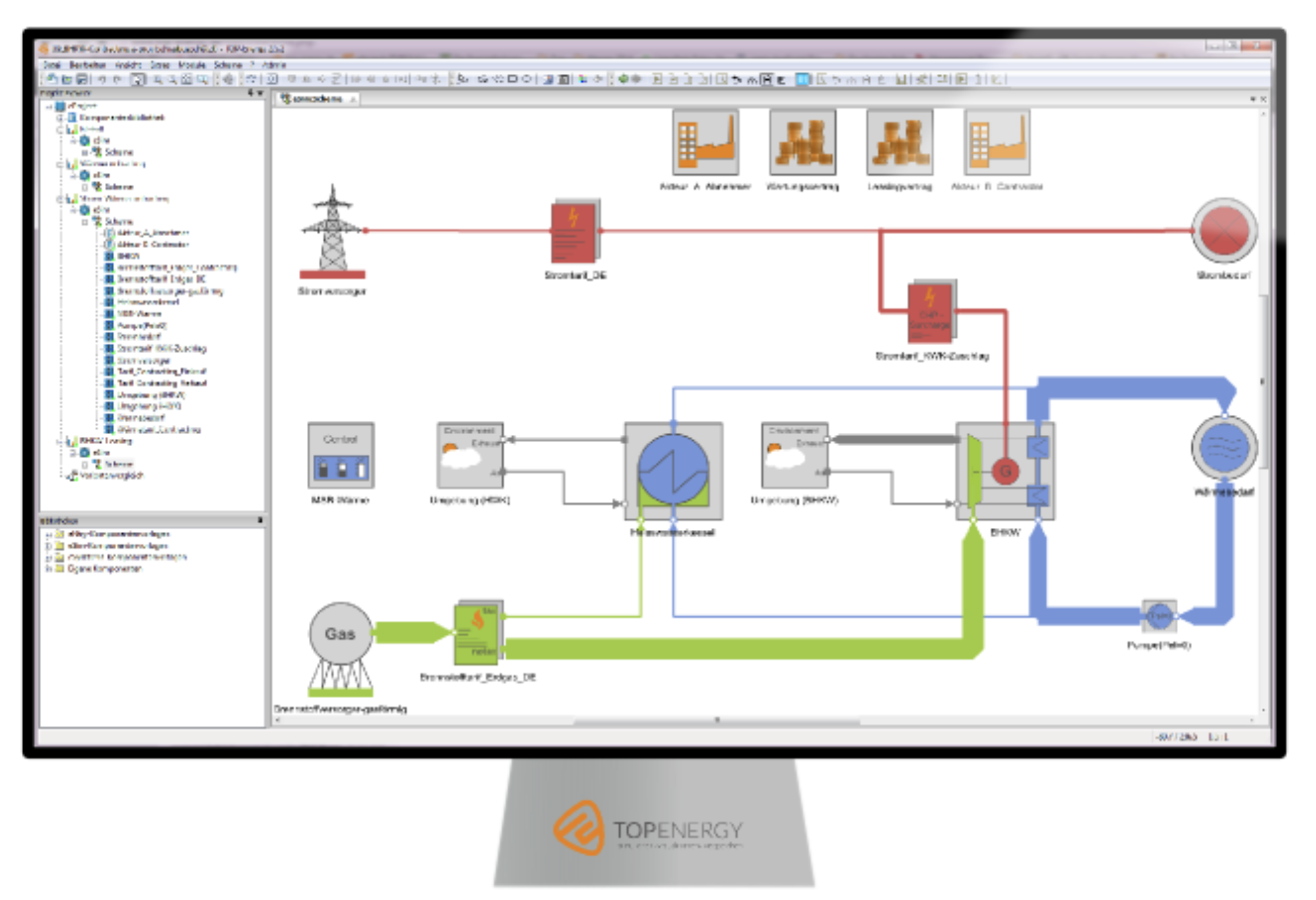

Economic assessment of energy supply by an energy contractor

Task

A contractor evaluates various possibilities for an alternative energy supply of an office building.

• Heat contracting

• Power heat contracting

• CHP leasing

Solution

Modelling the three energy supply options given by the contractors and comparing them to the reference case. In the reference case, the office building is supplied by district heat and the electricity needed is bought from the power market.

Outcome

All three of the given options provide potential for savings for both the contractor and the owner of the office building.

From the perspective of the owner of the office building, the best option is to lease the CHP from the contractor and sign an additional maintenance agreement (savings of 20% per year).

The most valuable option for the contractor however, is to run the CHP himself and sell the heat and electricity to the customer (payback period 2.5 years).